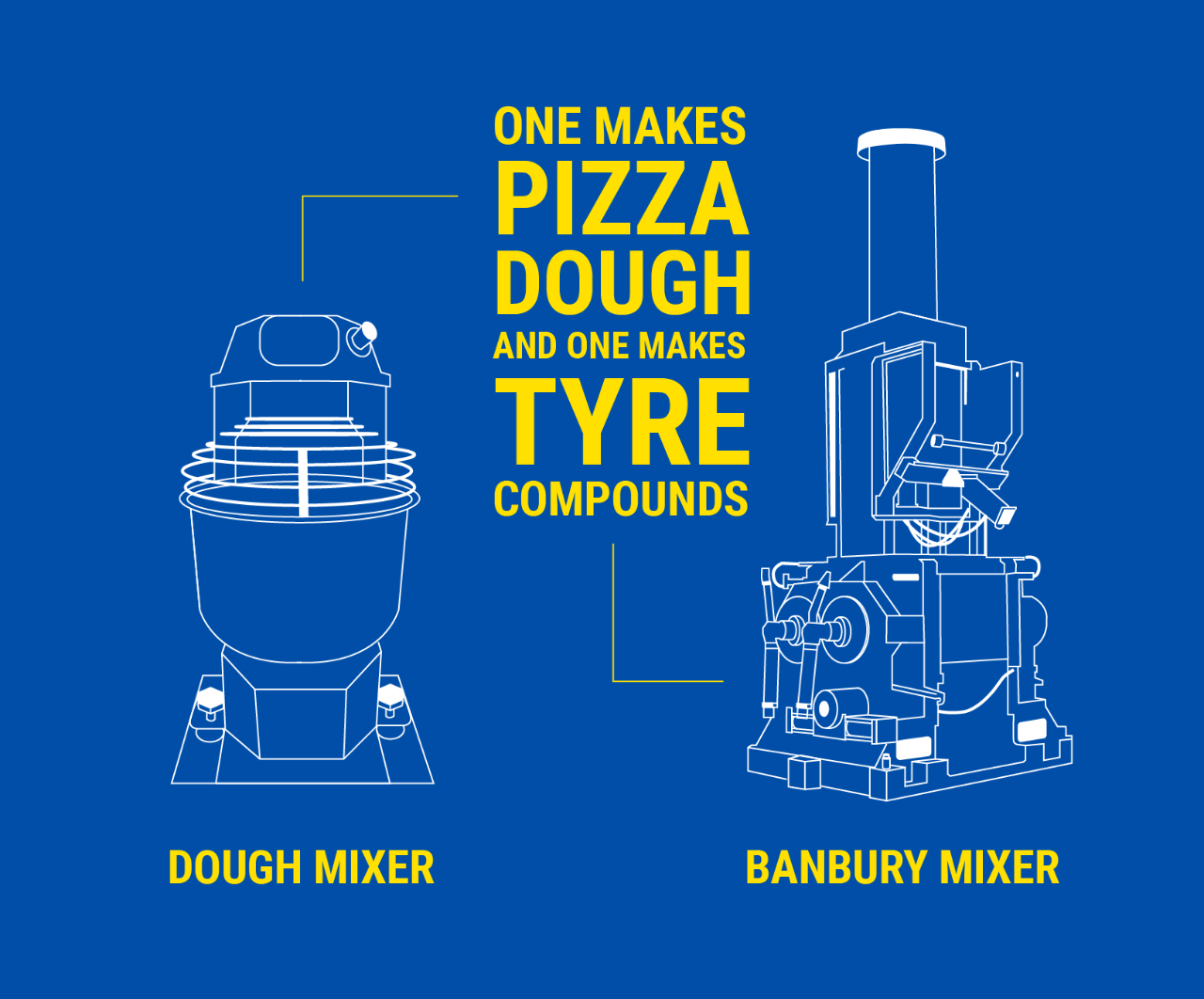

1. Ingredients are Blended Together

Rubber, fillers, antioxidants and other ingredients blended together to create a black, gummy compound that will be sent on for milling.

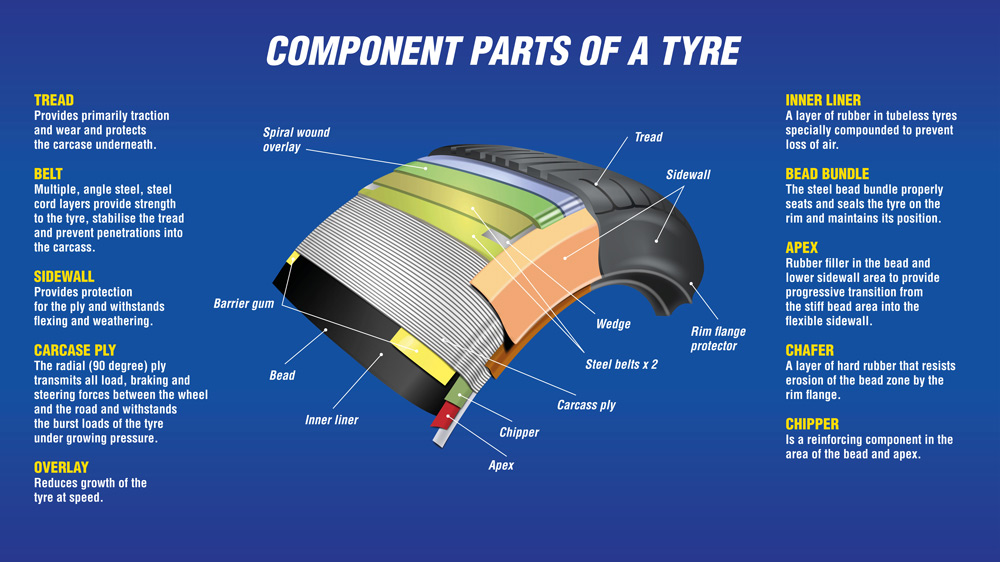

2. The Tyre Compound is Milled to Form the Basic Structure of the Tyre

The compound of ingredients from step one is milled and then cooled, before being cut into strips to form the basic structure of the tyre itself. Other elements of the tyre are also prepared at this stage, such as the fabric cords and steel belts.

3. The Tyre is Built from the Inside Out

Using special machinery, the materials that make up the tyre are assembled into what is known as a ‘green tyre’. Starting from the inside, the casing is built first, followed by the tread, shoulder and sidewall. The tyre is now starting to look like the finished article.

4. The tyre is Cured (or Vulcanised)

Using hot moulds in a curing press, the green tyre is then vulcanised, compressing all the parts of the tyre together and giving the tyre its final shape. This includes its tread pattern and manufacturer’s sidewall markings. It is this process of curing which enhances the tyre’s flexibility and elasticity.

5. Quality Control Inspections

No tyre is finished without being inspected to meet Goodyear’s high standard. This is a task performed by trained inspectors using special machinery. Some tyres will also be pulled from the line to be checked by x-rays. Not only that, but Goodyear’s quality control engineers will also randomly select tyres off the line and cut them open to ensure they meet our high standards.