What is a Goodyear DrivePoint?

Goodyear DrivePoint is a connected, yard-based drive-through tyre inspection system that allows automated and dynamic tyre pressure measurement.

Easily installed via wireless battery-powered technology, the solution allows dynamic and rapid inspections of large quantities of vehicles – which is ideal for fleets with vehicles returning frequently to the yard.

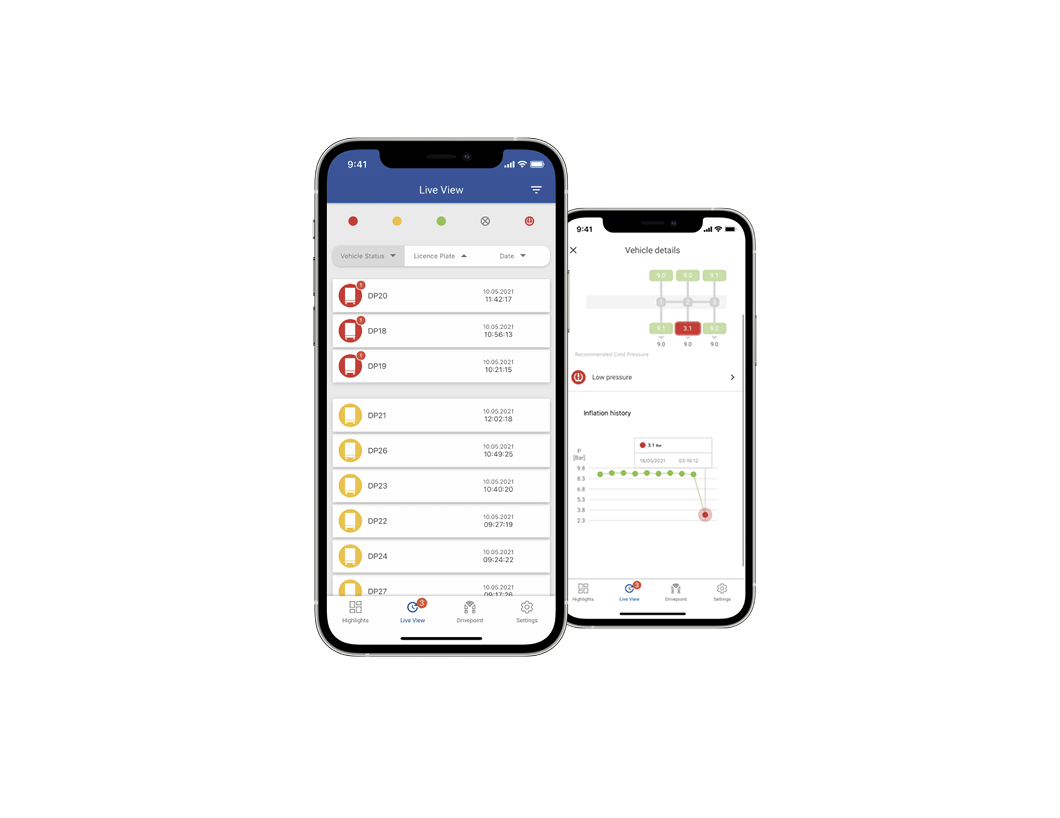

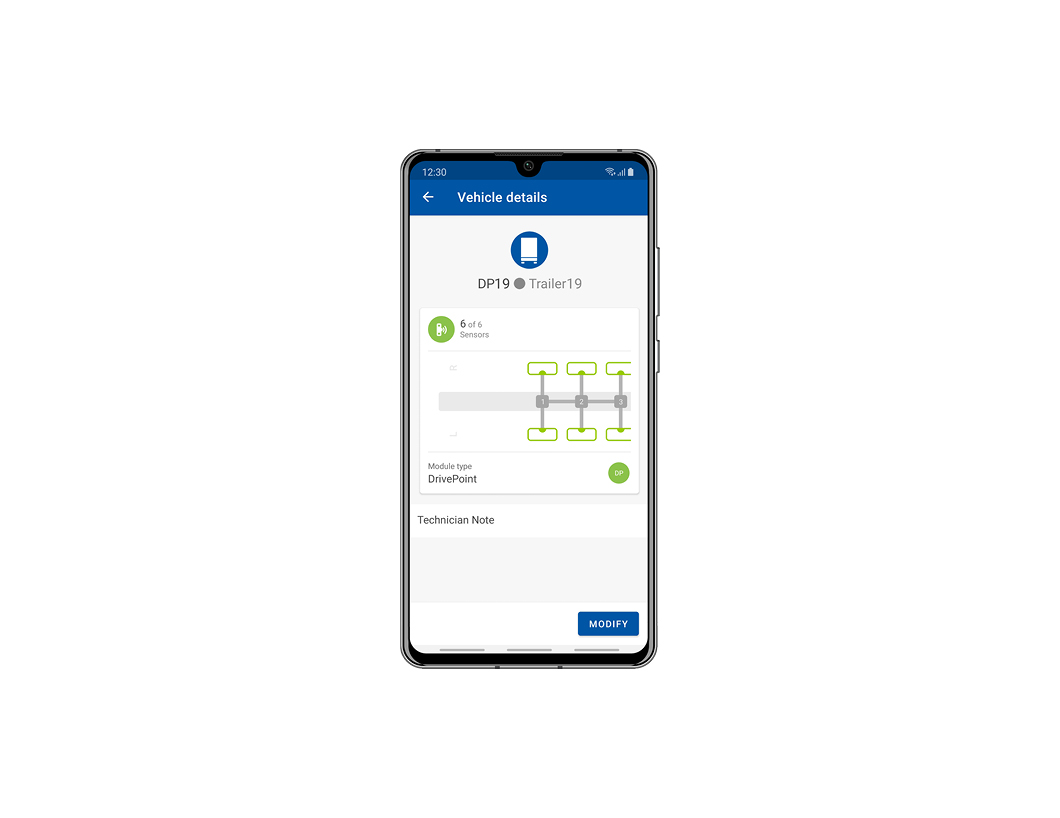

Combined with our user-friendly mobile and web applications, Goodyear DrivePoint supports an instant display of your tyre health allowing proactive monitoring and maintenance of your fleet.

What about the hardware? It is both simple and proven, comprising just two elements: on-valve sensors that fit easily onto the tyre valves and receivers for tyre data collection and processing.